Industrial manufacturing is experiencing a quiet revolution, and Near Net Shape (NNS) forgings are leading the charge. By combining precision engineering with material efficiency, this innovative approach is helping manufacturers across New Jersey and beyond cut costs, reduce waste, and produce stronger, more reliable components.

What Are Near Net Shape Forgings?

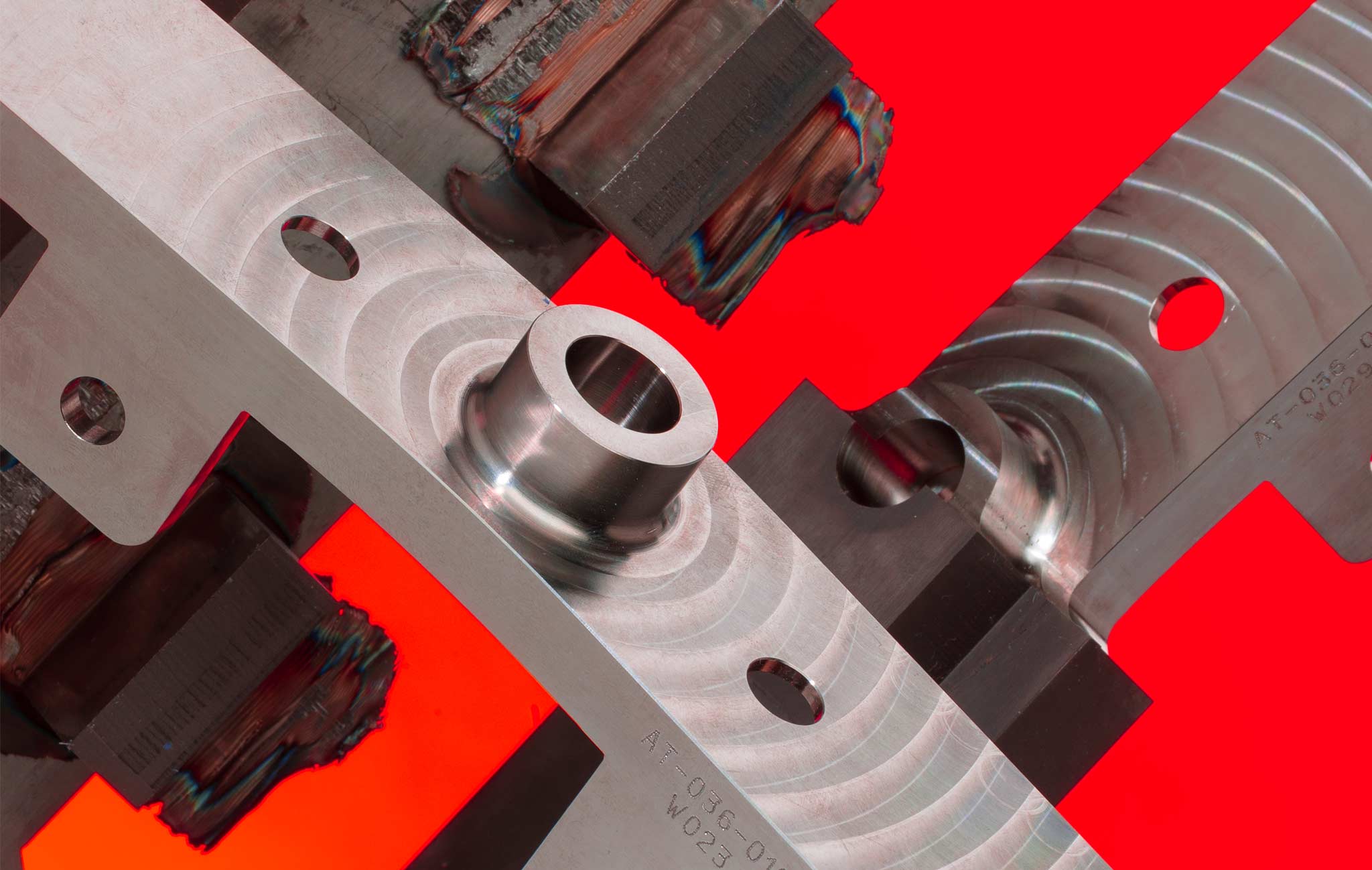

Near Net Shape forgings are specialized metal components designed to require minimal machining after forming, unlike traditional forged parts that often undergo extensive finishing. By creating parts closer to their final dimensions and shapes during the forging process, manufacturers can reduce material waste, tooling wear, and machining time, ultimately improving production efficiency and environmental sustainability.

This technique is particularly valuable in sectors like aerospace, automotive, heavy machinery, and energy, where strength, precision, and consistency are critical. Components made with NNS forgings often show enhanced mechanical properties, including higher fatigue resistance and improved structural integrity, making them a preferred choice for demanding applications.

All Metals & Forge Group Leads the Way

Ahead of FabTech 2025, All Metals & Forge Group (AMFG) announced the launch of its upgraded NNS forging capabilities. These improvements allow the company to deliver larger, more complex components with tighter tolerances, meeting the evolving needs of industrial clients. AMFG’s focus on innovation highlights how New Jersey manufacturers are embracing advanced technologies to remain competitive on a global scale.

Benefits Beyond Manufacturing

The advantages of Near Net Shape forgings extend beyond the production floor. By reducing material scrap and energy consumption, NNS components contribute to more sustainable manufacturing practices. This approach aligns with the growing demand for environmentally responsible industrial solutions, helping companies meet regulatory requirements and sustainability goals while maintaining high-performance standards.

Why This Matters for New Jersey Businesses

New Jersey has long been a hub for advanced manufacturing and industrial innovation. As companies adopt cutting-edge solutions like Near Net Shape forgings, they strengthen the state’s industrial ecosystem, create high-skilled jobs, and support sectors that are essential to both the regional and national economy.

By combining precision, efficiency, and durability, NNS forgings are setting a new standard for industrial manufacturing—demonstrating that smart design and advanced engineering can go hand-in-hand with sustainability and performance.

For more updates on industrial innovation and advanced manufacturing in New Jersey, visit the Explore New Jersey Business section